What’s the background of the project?

JC: “This project was commissioned by NineBot, a leading Chinese electric mobility company. The bike was developed by Segway in the US. Ninebot is the parent company of Segway. It is launching a line of electric scooters, they wanted a hallow product to headline the lineup and to showcase their technical prowess. They also want to gauge the public readiness to such a product.”

What is the design concept?

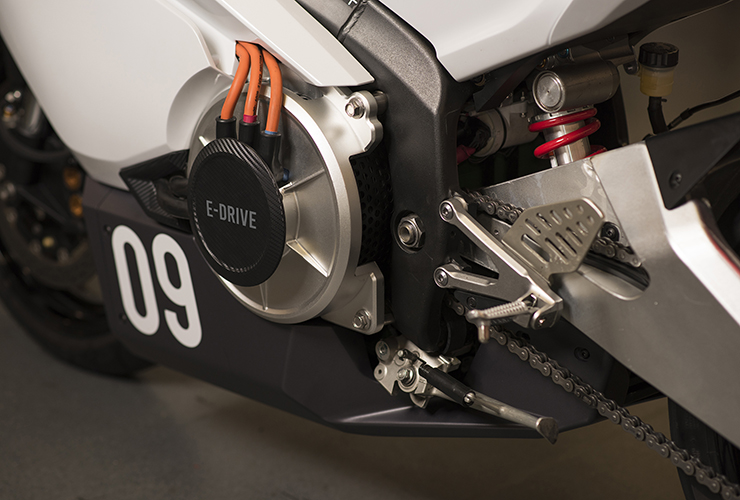

JC: “I want a clean and minimalist design that is part of the client’s product language. I also want something different from the current trend in transportation design, less saturation of visual stimulation. The excitement of a motorcycle can be expressed in a more subtle way, with proportion, strong character lines and clean surface treatment. The side panels are large and uninterrupted with minimal features. Key character lines came from folding of geometric surfaces to give it a sense of strength. The front fairing is minimalist by using clean surfaces with headlight tucked away, giving it a more neutral expression. The visual center of gravity is moved forward to create a sense of motion. The motor and the battery are exposed on each side to showcase the technology. They are also separated visually from the side panels to form a power unit to highlight the electric powertrain.”

What’s the design process?

JC: “When I started the project, we had 2 naked running chassis. We had 2 weeks of sketching to establish basic directions. Then we moved to the clay modeling. I’ve been a product designer for 20 years, I’m used to designing in 3D with CAD and no longer on paper with 2D. Luckily, the client was very accommodating. They let me explore design in 3D with clay. To save time and explore more options, we used each half of the clay for different directions until we had a solid solution. After that we scanned in the model and used the data as reference to build 3D model. For me, the clay model shows the volume and character. But the design has to be refined in CAD. After getting the design right, we handed the data to a superbly capable inhouse engineering team to convert the design data into actual parts to build the prototype and putting everything together. The whole process took about 7 months to complete.”

What’s the biggest challenge?

JC: “To convince the client of my vision. Because they wanted a flagship bike to showcase their technology, I think it should be a sportbike that looks super fast. So the proportion and a certain treatments would feel familiar to be recognized as a sportbike. But the client wanted something totally ground breaking and unseen before. I think that would result in a divisive design that might turn off a certain part of the market, often the hardcore riders. I believe a good design should have universal appeal. I’m glad they trusted my judgment to go with this refined, clean approach. So far the response from the internet has been overwhelmingly positive to the design.”

What you would have done differently?

JC: “Overall I’m very happy with how the project came out. I was able to build or go over most of the surfaces. But there were always a few details that slipped through. Just small things only the designer would see. For the future, it would be cool to design a bike from the ground up. Right now we have a repurposed chassis from an ICE bike, we had to make a lot of compromises. A purposely designed chassis and components would have created a much more optimized design. I want to make the battery and the motor the key elements of the design with very minimal body work. Everything is bolted onto a loadbearing power unit, simple and light.”

How to become a motorcycle designer?

JC: “I am an industrial designer and a rider. I have worked in NY for over 15 years. I knew I wanted to get into bike design, but I had no motorcycle designs in my portfolio. So I started by rebuilding bikes. I bought a Benelli TNT 600, I completely redesigned the bodywork including the subframe and exhaust system. The plan was to approach many of the Chinese motorcycle manufacturers for projects. But the project never finished beyond clay modeling because the shop I sourced was not able to build it to my spec. Nevertheless, that project got me 2 projects from another electric bike factory in China. Those projects did not go anywhere either. But they were great learning opportunities for me and that experience eventually landed me the Segway project. I was also lucky to have a good recommendation from a friend. I think I will continue to work this way, building my own projects and looking for collaborations.”

What about the future for 2 wheeled electric vehicles?

JC: “I really believe electric riding is the future. But the technology is not ready for mainstream adaptation. Some configuration like scooters is catching up faster than say sportbikes. The value proposition of the electric sportbike is not there yet. We still need better battery technology and cost reduction for this to go mainstream. But that day will come. Personally, I have an electric scooter and a traditional sportbike. Even though the scooter has limited performance compared to my motorcycle, I’m using it more these days because of its convenience. You learn to appreciate it for what it is. It is quiet and has an app for monitoring and tracking. You feel like you are riding the future. I can’t wait for the day when electric powertrain is mainstream.”