Bruno Forcella: “I always wanted to build a custom bike different from anything else. There had to be something about the bike that would differentiate it from all other custom-builts. Some bikes impress with big fat rear wheels, others convince with huge wheel diameters and small rims. No matter whether «Dragstyle», «Bobber» or «Old School», all three styles are powered by a combustion engine, most likely a V-Twin. Therefore, I decided to create a bike with an exceptional drivetrain.

There are already quite some electric motorcycles on the market, mainly scooters or motorcycles that look very similar to conventional ones. At first glance, you often don’t even recognize the bike being electric. However, there are also electric bikes that look so crazy you might think they come from space. An electric drivetrain comes with many benefits: The insane acceleration, almost no need for maintenance, direct torque, no oil, no gas, no exhaust, to name only a few. Nowadays the most important factor is the emission free means of transportation.

I am an electrical engineer. I have already developed hard- and software for electric motor control before. I decided to combine hobby and profession and build an Old School Chopper driven by a modern electric drivetrain. The design of the bike posed a tough challenge. How would I mount an electric motor and a square-edged battery in a cool attractive way on a chopper frame?

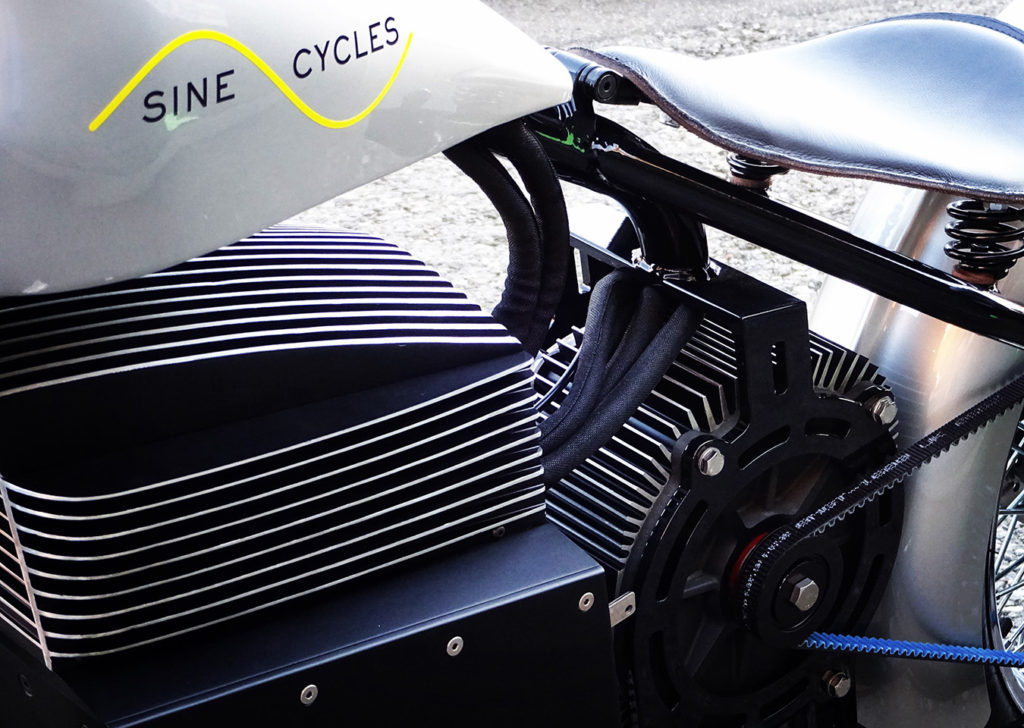

My main goal was to create a design that puts the electric drivetrain in the spotlight. I wanted the electric motor, the battery housing and the heatsink for the motor controller to be eye-catching but not overwhelming. In search of an electric drivetrain I came across the electric motorcycles from the Californian Company «Zero Motorcycles»: Advanced technology combined with a good-looking motor. I knew right away that their drivetrain was just the right choice for my bike.

A smartphone app with detailed information about the motorcycle such as the time until charged, average watts per mile, total charge cycles and much more was available as well. Fortunately, I was able to purchase the electric drivetrain from Zero Motorcycles. They usually do not sell their proprietary parts, only their complete models.

I was aware of the fact that I would not find a drivetrain-compatible motorcycle without the need for modifying the frame. I needed a frame, a fork, wheels and brakes. I found all these components on the chopper called «Tha Heist» from Cleveland Cyclewerks.

In a next step I designed a 3D model of all components making it easier to visualize the final design of the bike. I designed shapes that I was able to craft myself or could get fabricated for a good price. I modified sourced parts until they met my expectations. For instance, the Cole Foster gas tank; I only use it as a cover for a brackets in place. The opening for the gas cover was closed by welding some sheet metal to it. The motor holders and the fender struts and some other parts were laser-cut. Other parts I fabricated on milling and turning machinery.

Cockpit

The shape of the cockpit exactly fits the upper fork crown and has the same shape like the embedded digital instrument from Motogadget. Furthermore, the cockpit includes 6 coloured LEDs showing the SoC of the battery. Some standard LEDs for warnings, floodlight etc. are integrated as well. The housing for the cockpit was manufactured by means of the 3D printing process called selective laser sintering according to my design. The functions of the LEDs are pointed out by a self-designed PVC Sticker with the according symbols and notches for the LEDs and the digital instrument.

Heatsink

I feel that the heatsink for the motor controller turned out very well. It‘ s made out of 5 parts of extruded aluminium heatsinks. I shaped the cooling fins manually with electric grinders. The heatsinks and the battery housing parts were then sandblasted and thereafter black anodized. For the finishing touch I grinded off the upper surfaces of the cooling fins again.

I painted the motor black. Here too I grinded off the upper surfaces of the cooling fins. My goal was to build a custom bike just like many other bike builders do. I haven’t sold any bikes so far. The bike is one-of-a-kind. I have no idea how much time I spent designing and building it. Time doesn’t matter when you’re having fun doing something.”

Source & pictures: Sine Cycles

Picture Bruno Forcella: daguruphotography