B2B | Source: PYMCO Technologies | PYMCO’s history traces back to 2015 when Pierre-Yves and Marc decided to join forces to develop an automotive Ultra Fast DC Charger. One of the limiting factors in that particular development was the internal battery pack that had to be compact, safe and able to handle extremely high currents during sustained periods of time.

Unsatisfied with the idea of building a large one-piece non repairable battery pack and not able to find the right product on the market, the idea of a solderless, repairable and modular battery pack quickly became an evidence for them. They started to work on it aiming to fulfill the numerous high performance requirements of the project.

Six months later, the first prototypes were being tested and after a year of fine-tuning and improvements, the final version was ready to be patented and commercialised.

High-tech engineering

Fast forward a couple of years, Benjamin came aboard completing a core team whose skills span from the essential mechanical, electrical and software engineering all the way to the creative and commercial, not forgetting industrialisation and logistics. Drawing from their experience acquired working in a variety of fields spanning from Automotive and special vehicles to Aerospace and Railway, PYMCO’s team is not one to shy away from a challenging project.

Business

Responding to a strong market demand and an ever-growing customer list, PYMCO will open in 2022 a new automated 4.0 production unit with an output capacity of 15MWh/year. Easily scalable and with a low footprint, this unit will be replicated at will to follow its growth. Other projects are also in the works and will be unveiled in the coming months including innovative Battery Management Systems, modular battery packs as well as full-blown powertrain solutions! Stay tuned!

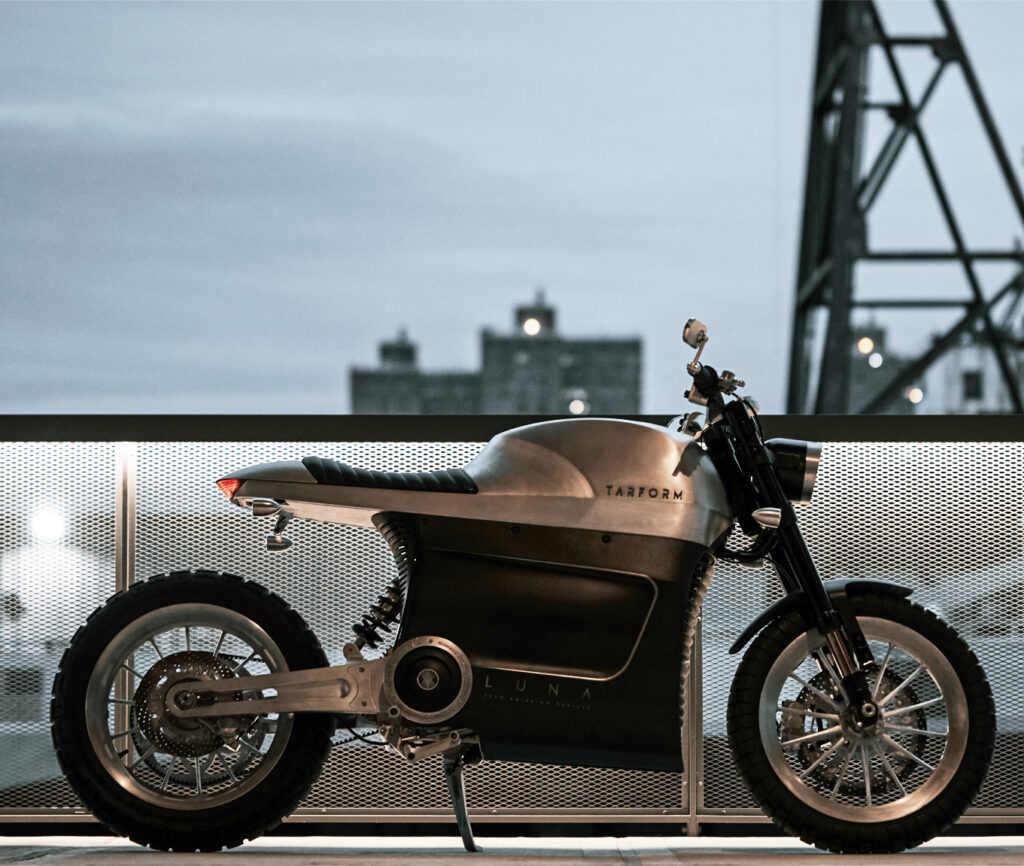

Passionate about motorcycles

With the addition of Benjamin coming from the motorcycle world with already a couple of projects under its belt (Jambon Beurre Motorcycles, Gloria Factory) and Pierre-Yves having retrofitted countless ICE bikes as well as being a co-founder of the E-Raw project, it was naturally that the PYMCO packs found their way into many 2-wheelers.

Their technical fit for these demanding applications are of course no stranger to their success. Below are a few of their characteristics:

- High power and energy-density

- Adapted to harsh environments

- High vibration resistance

- Easily cooled and warmed (thermal management)

- Compatible with complex custom shapes and volumes

- Highly connected and compatible with all common wired and wireless protocol

- Low environmental footprint through its re-usability and very long life

Today, PYMCO Battery packs are already mounted as OEM on high-end bikes such as the American TARFORM Luna or the French DAB Motors Concept-E.

Products & technology

Repairable Batteries

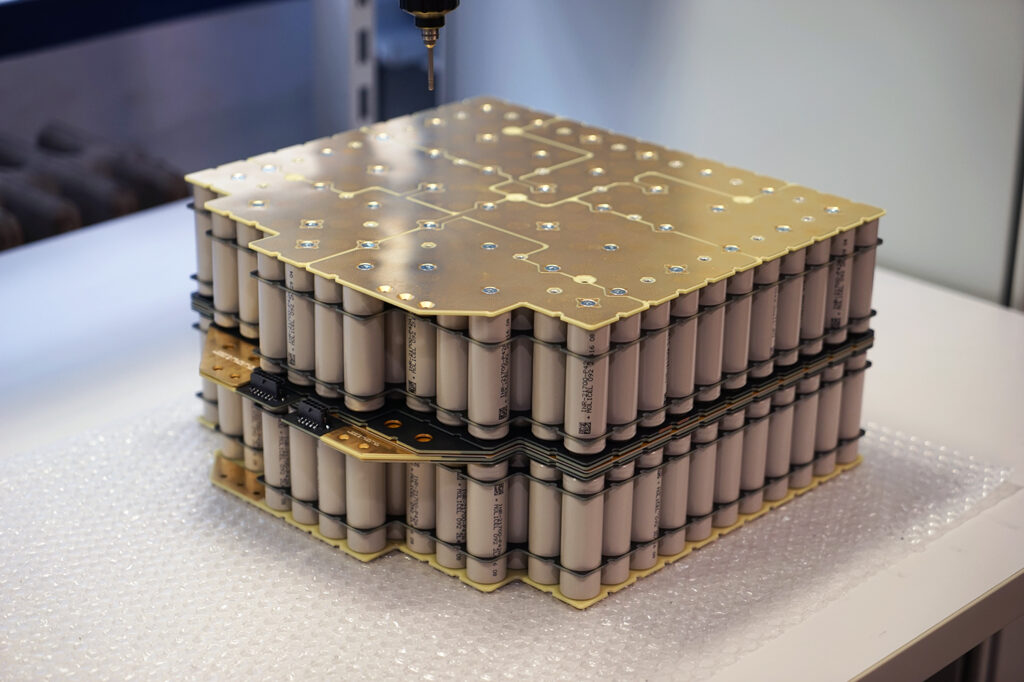

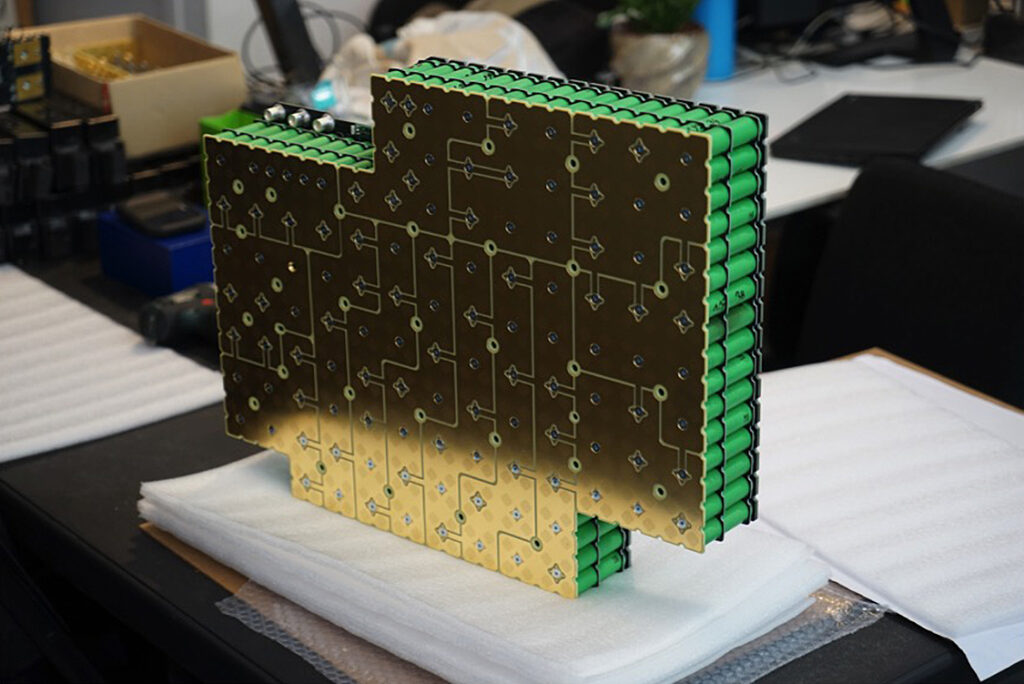

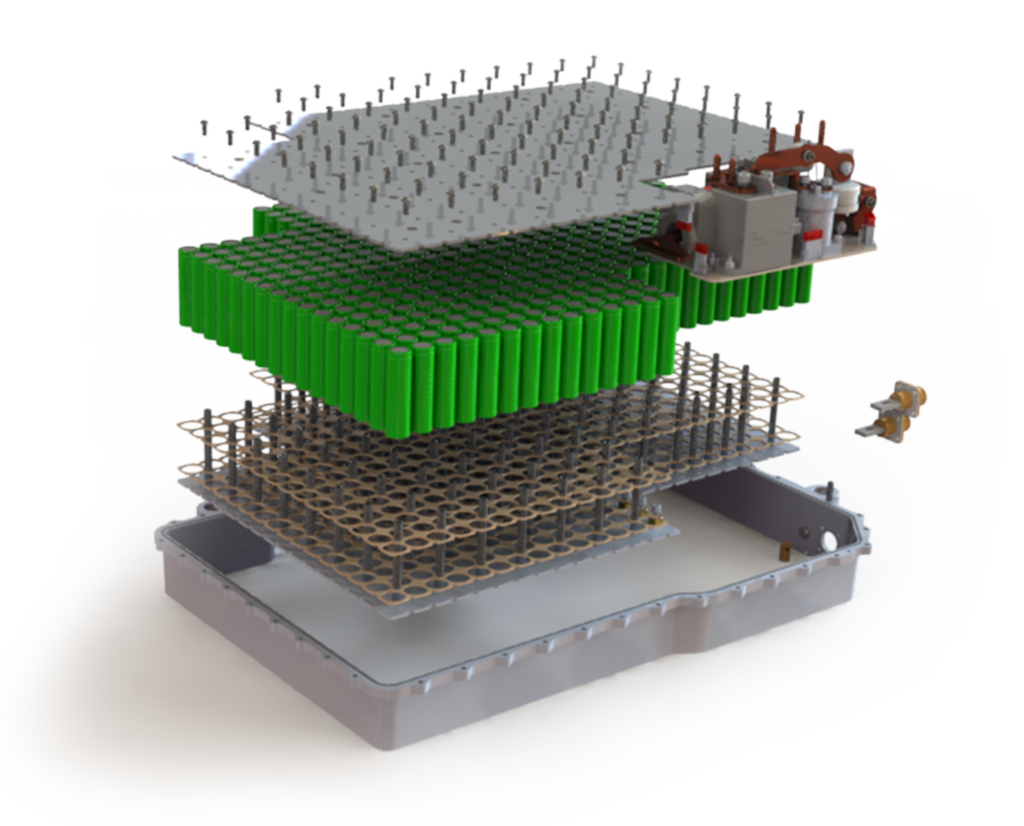

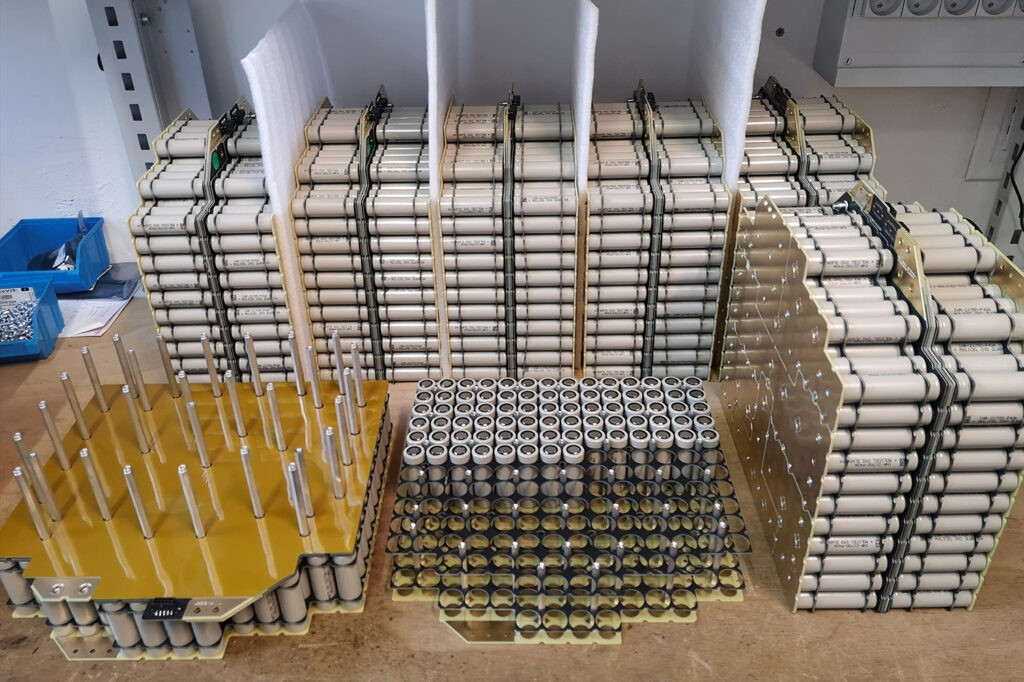

Departing from the obsolete and ubiquitous welded technology, PYMCO’s batteries are based on a solderless constant pressure contact that ensures a mechanical, electrical, and thermal coupling between all the cells of a battery pack. PYMCO’s mechanical assembly concept enables the customer to disassemble and reassemble the pack at any moment of its life. This advantage allow PYMCO to repair batteries that would have otherwise been discarded as well as collect old battery cells in order to:

- Send them for recycling in an intact physical condition.

- Send them for a second life (stationary, low power etc …)

- Replace them by brand new cells giving the pack its original or upgraded capacity and performance level for a fraction of the pack cost

High-Performance

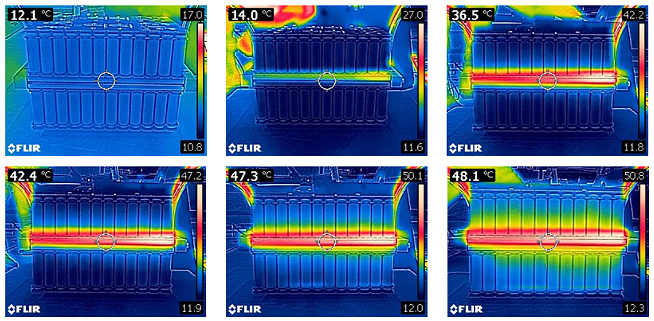

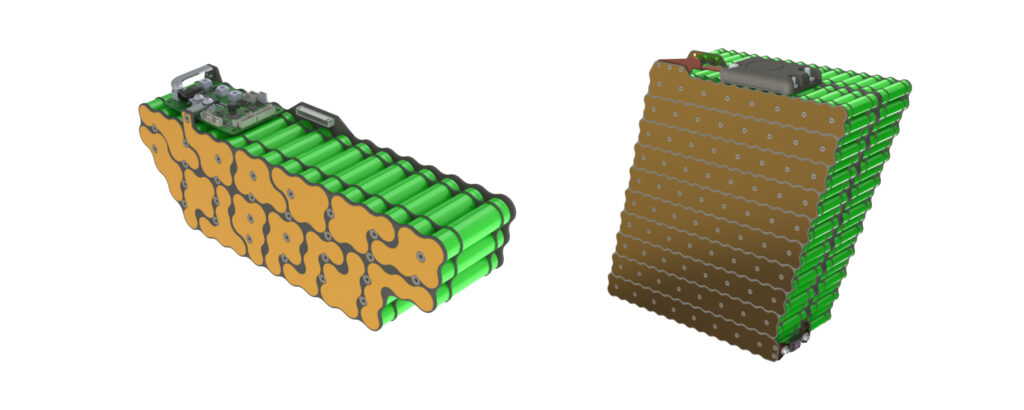

Given their size, electric motorcycles need to pull high currents from battery packs of limited size and capacity. This particular characteristic often drives the traditional battery assembly techniques to their limits. Pushing the boundaries of power density, PYMCO assembly technique is extremely efficient and performant giving best-in-class:

- Power management

- Thermal management

- Mechanical strength

The electrical contact ensured by constant pressure allows for currents up to 70A per cell and 1500A at the pack level (virtually unlimited). PCB strong dielectric characteristics allow for ultra-high voltages setups, up to 1500 V. The mechanical contact between the cells and the assembly ensures a strong metal to metal coupling from the cell to cooling surface giving strong benefits:

- Very low thermal gradient: cell temperatures are perfectly balanced and avoid the need for a dielectric liquid internal bath and its associated limitations (leaks, cost, weight etc.)

- Easy heat extraction and transfer to any active or passive cooling method (Heatsink, thermal mass, cold plates)

Customization

SHAPE

Anyone who tried one day to fit a battery pack in a motorcycle knows how daunting the task can be, especially when the design intent deviates from a cube or a parallelepiped. PYMCO’s packs are not limited to a specific shape or form and can be produced as close as it gets to the original designer’s vision.

CONNECTIVITY

Central to all new e-motorcycles, connectivity is an ever-growing need. As an answer to this demand PYMCO offers fully custom interfaces called BCU (for Battery Control Unit) that includes:

- Power management

- “Hot swap” multi-pack coupling

- Wifi / Bluetooth / 3G / 4G up and down-link

- Integrated DC-DC for 12V output

- Pre-load management

- Custom analog interfaces

- CANbus / RS485 / EtherCat communication

Scalable Industrial Solution

Leveraging the PCB industry strength and commoditization, PYMCO packs are highly scalable and supply-chain secure.

The fast and very simple assembly steps allow swift time to start-of-production with minimal equipment all the while keeping the exact same product as on a fully automated assembly line.

To integrate and secure a safe supply chain, PYMCO Technologies offers highly-flexible production scenarios including:

- Multiple sources on cell supply

- Multiple sources on pack assembly components

- Multiple assembly locations including partial or complete under-license vertical integration at the customer’s facilities